快速链接

系统概述

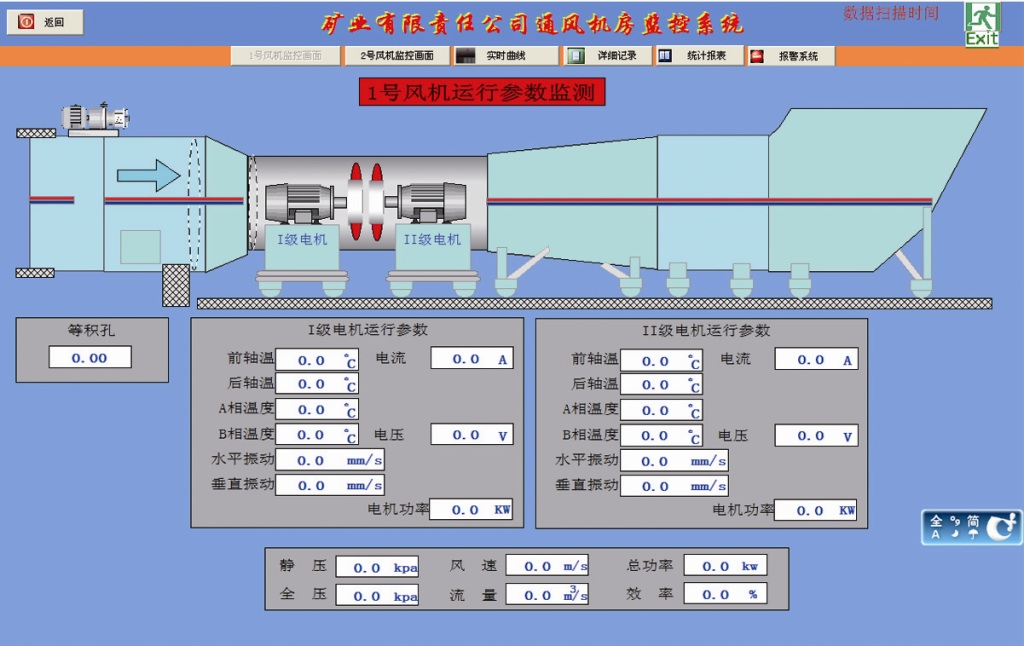

由于矿山作业对通风的特殊要求,通风系统、设施的可靠性承担着巨大的责任,一个良好的通风系统就是一个矿的巨大财富。矿用主通风机在线监控与故障诊断系统主要是针对金属矿山主通风机研发。该系统符合最新版《金属非金属地下矿山监测监控系统建设规范》,参考标准MT 421-1996《煤矿用主要通风机现场性能参数测定方法》、 GB/T 10178-2006《工业通风机现场性能试验》为依据,应用工业计算机监测技术对矿用大型通风机的运行状态进行连续在线测量与处理,以多种方式提供通风机运行状态的各种数据,保障通风机的安全运行和方便风机的性能测试。

本系统采用国际先进的研华工业控制计算机及西门子300系列PLC,防尘、抗震、抗干扰能力强,性能稳定,功能强大,扩展方便;测量传感器、变送器均选用国际国内名牌产品,误差小于0.5%;输入通道板的分辨率为1/27648,系统采用一系列抗干扰措施,保证测量误差小于2%。

System overview

Due to the special requirements of mine operation for ventilation, the reliability of ventilation system and facilities bears great responsibility, and a good ventilation system is a great wealth of a mine. The online monitoring and fault diagnosis system of mine main ventilator is mainly developed for metal mine main ventilator. The system conforms to the latest edition of the "Metal and Non-metal underground mine monitoring and monitoring system construction Code", referring to the standards MT 421-1996 "Main fan field performance parameter determination Method for coal mine", GB/T 10178-2006 "Industrial fan field performance test" as the basis. The industrial computer monitoring technology is applied to continuously measure and process the running state of the large fan used in mining, and various data of the running state of the fan are provided in various ways to ensure the safe operation of the fan and facilitate the performance test of the fan.

This system uses the international advanced Advantech industrial control computer and Siemens 300 series PLC, dustproof, seismic, anti-interference ability is strong, stable performance, powerful function, easy to expand; Measuring sensors, transmitters are selected international and domestic famous brand products, error is less than 0.5%; The resolution of the input channel plate is 1/27648, and the system adopts a series of anti-interference measures to ensure that the measurement error is less than 2%.

系统功能特点

系统具有在线帮助、状态监控、故障报警、信息查询与打印、数据远程传输、远程控制六大功能。

1)监测电机电量参数:三相电压和线电压、三相电流,有功功率、无功功率、视在功率、功率因数,频率等电量;

2)监测电机定子每相绕组温度,轴承两端温度(电机自带温度传感器);3)监测风机的水平和垂直振动;

3)监测风机静压、全压、静压效率、全压效率、风速、流量;5)监测一氧化碳浓度;

4)监测风机开停信号、正反风信号,变频器运行状态;

5)控制主通风机正常状态下的开、停,控制矿井需返风时的倒转反风;

6)远程手动/自动转速调节(变频电控):在监控界面手动输入频率,或由压力传感器信号反馈回来,系统根据该信号进行自动反馈调节变频频率来改变风机转速,两种方式由操作员选择;

7)自动记录通风机运行时的监测参数值,并自动生成表格,有关信号的图谱、曲线图以及数据显示直观简明;提供历史数据的查询;

8)显示系统的实时报警信息,并提供历史报警信息的查询;

9)主通风机监控系统具有工业以太网接口、PROFIBUS DP总线接口、CAN现场工业总线接口、RS485总线接口,可接入其他监控设备和传感器。可接入单位监控系统网络平台,实现监控数据网络共享,经授权的网络终端用户随时监测通风机的状态、运行数据、故障情况,具有系统和节点自诊断功能,并可对通风机远程操作和管理;

10)远程监控站在线帮助功能,在接到用户请求帮助的消息后,弹出一个关于相关主题的帮助窗口,将用户所需的帮助信息显示出来。操作人员可随时查询帮助文件,解决操作中遇到的疑难问题。

System function characteristics

The system has six functions: online help, status monitoring, fault alarm, information query and printing, remote data transmission and remote control.

1) Monitoring motor power parameters: three-phase voltage and line voltage, three-phase current, active power, reactive power, apparent power, power factor, frequency and other power;

2) Monitor the winding temperature of each phase of the motor stator and the temperature of both ends of the bearing (the motor comes with a temperature sensor); 3) Monitor the horizontal and vertical vibration of the fan;

3) Monitor the static pressure, total pressure, static pressure efficiency, total pressure efficiency, wind speed, flow rate of the fan; 5) Monitoring carbon monoxide concentration;

4) Monitor the fan start and stop signal, positive and negative wind signal, inverter operation status;

5) Control the opening and stopping of the main ventilator under normal conditions, and control the reverse reverse air when the mine needs to return air;

6) Remote manual/automatic speed adjustment (frequency conversion electronic control): manually input the frequency in the monitoring interface, or the pressure sensor signal feedback back, the system according to the signal automatic feedback to adjust the frequency conversion to change the fan speed, the two ways are selected by the operator;

7) Automatically record the monitoring parameter values of the fan during operation, and automatically generate a table, and the graph, curve and data display of the relevant signals are intuitive and concise; Provide historical data query;

8) Display real-time alarm information of the system, and provide historical alarm information query;

9) The main fan monitoring system has industrial Ethernet interface, PROFIBUS DP bus interface, CAN field industrial bus interface, RS485 bus interface, and can access other monitoring equipment and sensors. Can access the unit monitoring system network platform, to achieve monitoring data network sharing, authorized network end users at any time to monitor the status of the fan, operating data, fault situation, with the system and node self-diagnosis function, and can remotely operate and manage the fan;

10) Remote monitoring station online help function, after receiving the user's request for help message, pop up a help window on related topics, the user needs to show the help information. Operators can query help files at any time to solve difficult problems encountered in the operation.