快速链接

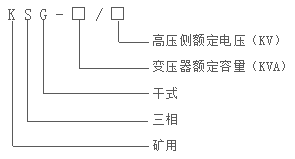

矿用一般型干式变压器符合国家标准:GB/T 12173-2008

The general dry type transformer for mining meets the national standard: GB/T 12173-2008

一、技术参数

(1)额定电压(KV):高压:10.5kV、低压:0.4KV

(2)系统最高运行电压:高压10KV

(3)额定频率(HZ):50

(4)相数:三相

(5)冷却方式:ANAF

(6)联接组标号:Y,d11

(7)变压器外壳为不锈钢外壳,外壳外部明显处有“高压危险,请勿接近”“严禁带电开盖”等安全警示语,外壳能承受7J的外作用力,不损坏。

(8)外壳的爬电距离及电气间隙:符合GB3836.3-2010第4.3条的规定。

(9)防护等级:IP54

1. Technical parameters

(1) Rated voltage (KV) : High voltage: 10.5kV, low voltage: 0.4KV

(2) The maximum operating voltage of the system: high voltage 10KV

(3) Rated frequency (HZ) : 50

(4) Number of phases: three phases

(5) Cooling method: ANAF

(6) Connection group label: Y, d11

(7) The transformer shell is a stainless steel shell, and there are obvious safety warnings such as "high voltage danger, do not approach" and "no live open cover" on the outside of the shell. The shell can withstand the external force of 7J and is not damaged.

(8) The creepage distance and electrical gap of the shell: in accordance with the provisions of GB3836.3-2010 Article 4.3.

(9) Protection level: IP54

二、技术特点

(1)干式变压器绕组采用树脂浇注式结构,选用高导电率的铜导线,高压绕组为分段层式线圈,低压绕组为薄式线圈。具有良好的绝缘结构,设有轴向风道,散热性良好,保证在封闭的变压器柜内全容量运行时,各部位温升满足国家相关标准。变压器不会因温度的变化在寿命期限内导致线圈表面龟裂。

(2)噪音水平:根据国家标准GBT 50087-2013 ,变压器本体声压级测定小于60分贝。

(3)变压器风扇的配置和布置应合理,风扇手动及自动控制,并可通过操作开关实现不同运行状态。散热风扇采用幕帘式通风机,当强迫风冷时,可提高变压器容量,且各部位温升仍能满足国家相关标准。

(4)变压器为三相、双线圈、铜导线、无载调压、树脂浇注式、空气自冷加风冷;

(5)受安装场地限制,在变压器安装时,可方便拆卸外壳;

(6)相同规格的干式变压器,机械部件可以互换;

(7)变压器不锈钢防护外壳厚度2mm,外壳防护等级IP54,外壳上装有牢固加强筋板,具有一定的抗爆破气流冲击能力;柜门带闭锁和报警装置,外壳可开启位置提供明显安全警示标识,可拆卸。壳体有满足散热要求的通风口,通风口具有滤尘、防水、阻燃、抗老化等特性。外壳外部设有观察窗,方便观察设备运行时的工作状态。

(8)寿命年限:在正常运行和维护条件下30年;

(9)变压器内所有材质都具有阻燃性,不自燃,不产生有害气体;

(10)变压器设置智能接口的温控系统,用于自动监测并巡回显示三相最热点温度、控制风机启停,超温报警及断路器跳闸。变压器正常运行的冷却方式为自然风冷,但提供冷却风扇满足强迫风冷条件下115%的过负荷要求。

2. Technical characteristics

(1) The dry transformer winding adopts the resin cast structure, the selection of high conductivity copper wire, the high voltage winding is the segmented layer coil, and the low voltage winding is the thin coil. It has good insulation structure, axial air duct, good heat dissipation, and ensures that the temperature rise of each part meets the relevant national standards when the full capacity is operated in the closed transformer cabinet. The transformer will not cause the coil surface to crack due to temperature changes during its life.

(2) Noise level: According to the national standard GBT 50087-2013, the sound pressure level of the transformer body is determined to be less than 60 dB.

(3) The configuration and layout of the transformer fan should be reasonable, the fan can be manually and automatically controlled, and different operating states can be achieved by operating the switch. The cooling fan adopts curtain fan, which can improve the transformer capacity when forced air cooling, and the temperature rise of each part can still meet the relevant national standards.

(4) The transformer is three-phase, double coil, copper wire, no-load voltage regulation, resin pouring type, air self-cooling and air cooling;

(5) Limited by the installation site, the shell can be easily removed when the transformer is installed;

(6) The same specifications of dry transformers, mechanical parts can be interchangeable;

(7) The thickness of the transformer stainless steel protective shell is 2mm, the protection grade of the shell is IP54, and the shell is equipped with a firm reinforcement plate, which has a certain ability to resist the impact of blasting air; Cabinet door with locking and alarm device, shell can be opened to provide obvious safety warning signs, removable. The shell has a vent to meet the heat dissipation requirements, and the vent has the characteristics of dust filter, waterproof, flame retardant, anti-aging and so on. The outer shell is provided with an observation window, which is convenient to observe the working state of the equipment during operation.

(8) Life span: 30 years under normal operation and maintenance conditions;

(9) All materials in the transformer are flame retardant, no spontaneous combustion, no harmful gases;

(10) The temperature control system of the transformer is set up with an intelligent interface, which is used to automatically monitor and display the three-phase hot spot temperature, control the fan start and stop, overtemperature alarm and circuit breaker trip. The cooling method for normal operation of the transformer is natural air cooling, but the cooling fan is provided to meet the overload requirement of 115% under forced air cooling conditions.